-

UP Company Profile

- Company Profile

- Organization Chart

- Research & Development

- Honor & Certification

- Corporate Culture

- Address

- UP Furnace factory

- History

-

UP Furnace factory

UP FURNACE CO., LTD. was founded in 2018, a wholly-owned subsidiary of SHENDA ELECTRIC GROUP CO.,LTD, specializes in R&D, manufacturing, installation, maintenance and transformation of electric furnace products and EPC contracting business of metallurgical engineering. It is an emerging company for various large-scale steelmaking electric arc furnaces, ladle refining furnaces and large non-standard heat treatment furnace and other products in China.

Design and manufacturing capability:

1.Steelmaking electric arc furnace: the main equipment for smelting scrap steel, currently widely used three-phase AC arc smelting, there are three kinds of power configuration of ordinary power, high power and ultra-high power, rated capacity from 1.5t to 150t.

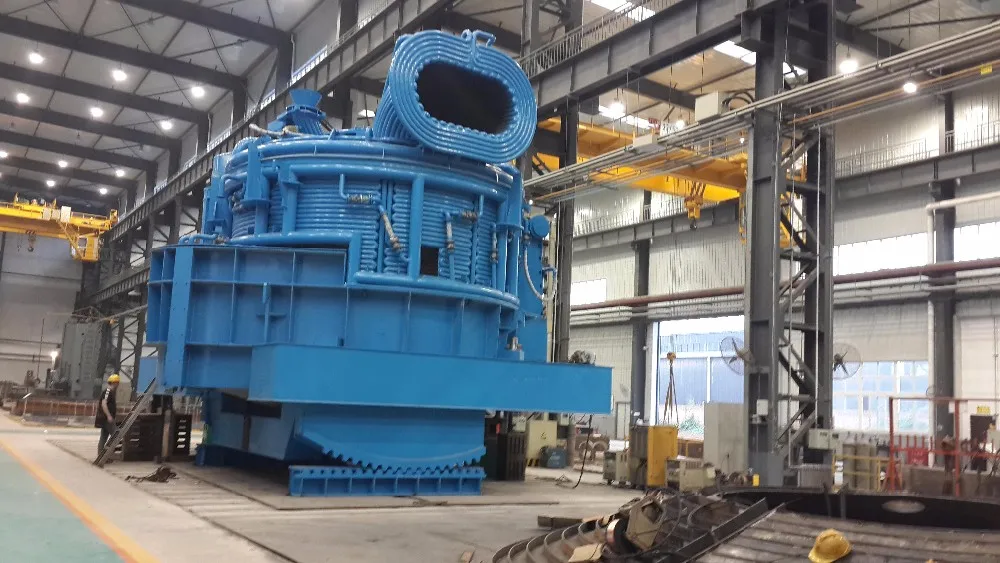

2.Ladle refining furnace: including LF, VD, VOD, VAD, RH and other furnace types, the most commonly used is LF ladle refining furnace, rated capacity from 10t to 300t.

3.Submerged arc furnace: mainly includes ferrosilicon furnace, ferromanganese furnace, ferrochromium furnace, ferronickel furnace, calcium carbide furnace, industrial silicon furnace, etc. The power is from 6300KVA to 48000KVA.

Headquater office in Jiangshan city,zhejiang,China

Sales manager and engineers

Our company's staffs had led the cooperation projects of the original Pengyuan Electric Furnace with famous manufacturers such as VAI of Austria, AICHELIN, ELKEM of Norway, CLECIM of France, SMS-DEMAG of Germany, DANIELI of Italy and TENOVA etc. The above cooperation projects all represented the national manufacturing standard of China large-scale electric furnaces in different historical periods; They also participated in the implementation of the original Pengyuan Electric Furnace Vietnam SSC 250,000 tons annual output of steel-making stage I and II project, Vietnam HOAPHAT 350,000 tons annual output of steel-making project, Vietnam HTP 500,000 tons annual output of steelmaking project, Bangladesh AKG first stage 1.3 million tons annual output of electric furnace steelmaking technology and steel plant design project, Russia TEMPO company 500,000 tons annual output of rebar steel plant complete metallurgical equipment project.

furnace cover welding workshop equipments

welding works frame structure in production furnace roof

ladle furnace painted painted part pipe structures

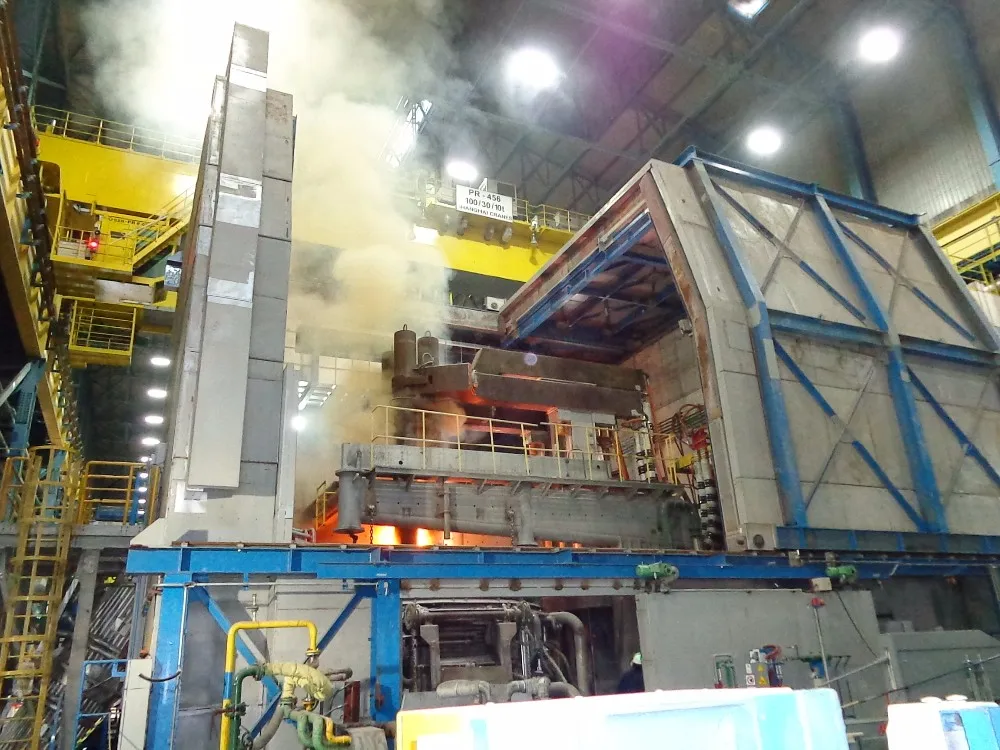

Electric Arc Furnace

Overview:

Steelmaking electric arc furnace is divided into normal power, high power and ultra high power according to matched power. It also can be divided into independent foundation, conjoined foundation, large pivotal bearing and four connecting link structure by roof rotating mechanism. There are left operation and right operation types for user's selection. According to the loading method, it can be divided into horizontal continuous feeding type electric arc furnace and furnace lid rotating top-opening feeding type electric arc furnace.The electric arc furnace consists of furnace body, furnace roof, tilting device, furnace lifting & rotating device, electrode lifting device, water-cooling device, hydraulic device, furnace transformer, secondary busbar, HV cabinet, LV electric and automatic control system etc, Capacity of EAF manufactured by our company is 10t-220t.

Function

1. Used for scrap melting, decarbonization, dephosphorization, desulfuration, deoxygenation

and molten steel heating etc, for melting steel of different grades and components.

2.Partial hot metal charging or charging pig iron, sponge iron (DRI) and hot briquetted iron (HBI).

3. Additional charging during the melting process and primary alloying process.

Characteristics

1. Refractory material saving due to the water cooled roof and water cooled panels.

2. Slagless tapping and tapping temperature reducing result from EBT.

3. Impendence of large current reducing due to the cooper and steel composited conductive arm and large section water cooled cable.

4. Power consumption for per ton of steel and smelting period are reduced due to adopting furnace door C-O lance and furnace wall coherent oxygen lance.

5. Fume collection rate is increased due to adopting furnace roof fourth hole and other fume discharging methods.

6. Scrap steel continuous charging and preheating system could be applied thus save energy, reduce consumption and improve smelting efficiency.

7. Raw material (DRI, HBI), lime and alloy automatic charging system could be equipped.

8. Equipped with advanced PLC control system and smelting model.

Horizontal continuous feeding type EAF product

Address:No.8 Zhenwu Road,Jiangshan Economic Development Zone,Zhejiang,China

Tel.:0086-0570-4221172

Fax:0086-0570-4221132

Postal code:324102

Email:info at upfanace.com

Website:www.upfurnace.com